Natural gas liquefaction

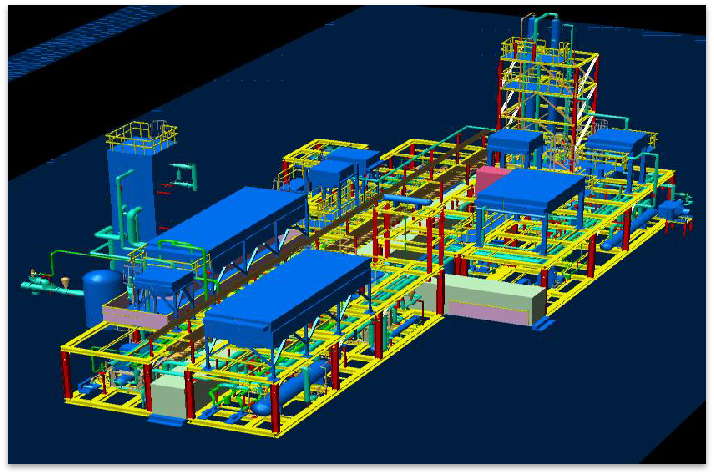

Provide natural gas liquefaction solutions within the range of 1MMSCFD to 20MMSCFD based on the actual needs of customers. It is primarily applied to the liquefaction of conventional and unconventional gases such as wellhead gas, associated gas in oil fields, coalbed methane, and shale gas. The equipment features modular and skid-mounted design, with a reasonable layout and compact structure, allowing for rapid installation, debugging, and commissioning upon arrival at the site, provided that the civil engineering conditions are met.

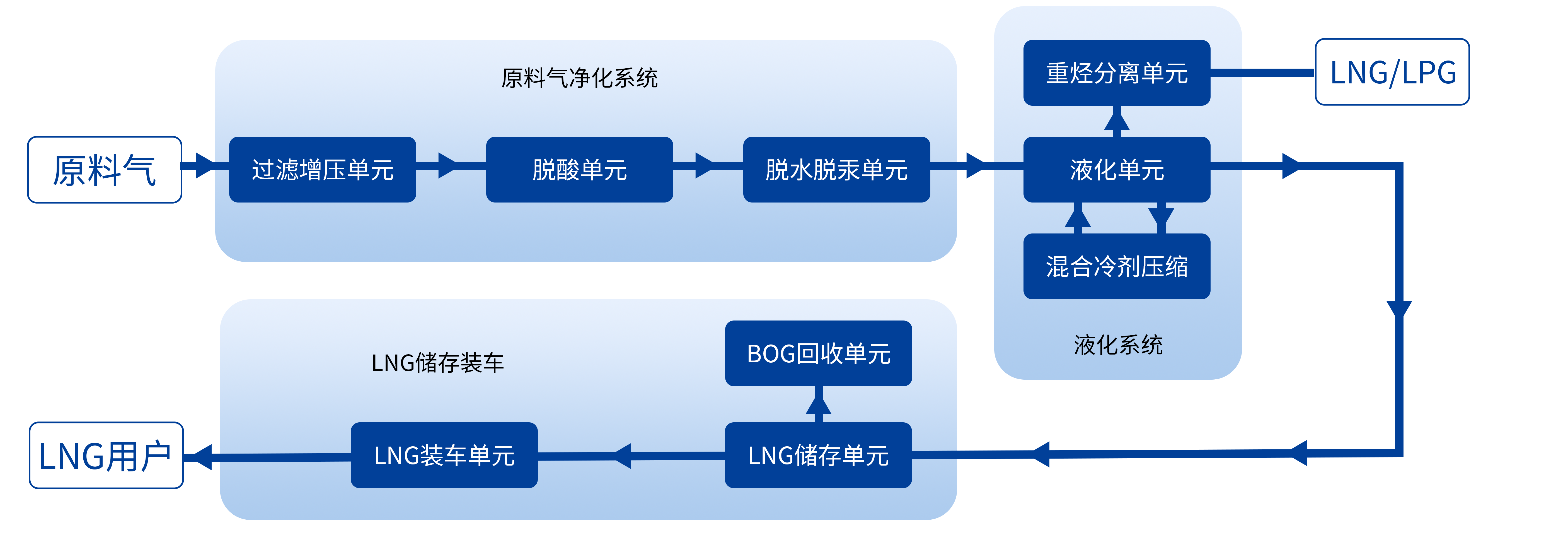

The following figure shows a typical natural gas processing plant flow

ADVANTAGE

Advantage

Advanced liquefaction technology

- The natural gas liquefaction process has reached an internationally advanced level. The mixed refrigerant cooling process in the second and third stages is currently the best in terms of adjustability and the lowest energy consumption among MRC processes, with dozens of successful cases in LNG plants.

- The overall energy consumption of the plant is low, with the unit product electricity consumption at 0.35-0.45 KWh/Nm³.

- It is easy to operate and offers great operational flexibility.

Integrated skidding and modular design

- Skid-mounted and modular manufacturing occupies a small area;

- factory prefabrication allows for simple and rapid on-site installation, shortening on-site construction time.

Short project construction period and quick production

- Provide overall planning for owners in aspects such as design, procurement, construction, and acceptance to shorten the entire project cycle.

- The success rate of initial production is 100%, with the shortest production time being 10 hours.

High degree of automation

- The design concept of “unmanned operation and minimal human intervention” reduces the staffing of the facility and minimizes the risk of operational errors;

- The entire system can achieve full automation and remote control (except for loading).

Professional technical team

- KERUI has many years of experience in EPC engineering, with more than 100 engineering technicians.

- We provide high-quality process design, engineering design, equipment procurement, and construction management.

- We offer comprehensive technical services, including personnel training and operation maintenance.

- We have 57 global branch offices, 33 regional service centers, and spare parts warehouses, with 24-hour face-to-face communication on-site.

Powerful production and manufacturing capabilities.

- Relying on its own production facilities, it can efficiently and qualitatively complete the processing of natural gas and the manufacturing and assembly of LNG units.

- It is capable of independently designing supporting compressor units that include imported engine heads such as Ariel and GE.